Understanding the Significance of Light Weight Aluminum Spreading in Modern Production Processes

Aluminum casting has emerged as a crucial element in contemporary production. Its sturdy and lightweight nature adds substantially to various industries, from vehicle to electronic devices. On top of that, advancements in casting techniques enhance production efficiency and quality. As producers seek ingenious solutions, the role of aluminum spreading in sustainability comes to be significantly relevant. This discussion will explore the complex importance of aluminum spreading and its effects for the future of production. What exists ahead in this developing landscape?

The Advantages of Aluminum Spreading in Production

Aluminum casting offers various benefits that enhance its appeal in modern-day manufacturing processes. One major advantage is its light-weight nature, which causes reduced power intake and enhanced fuel performance in transportation applications. In addition, light weight aluminum's exceptional corrosion resistance expands the lifespan of actors products, making them a lot more sturdy in different environments. The product likewise promotes intricate layouts and complicated geometries, enabling producers to create parts that fulfill exact specs.

Furthermore, light weight aluminum casting flaunts a reasonably low melting point, which conserves energy throughout the manufacturing procedure. This quality likewise makes it possible for rapid cycle times, raising general productivity. In addition, the recyclability of aluminum adds to sustainability efforts, as recycled aluminum needs considerably less power to process compared to main light weight aluminum. Jointly, these benefits position aluminum spreading as an important method in contemporary manufacturing, catering to the needs for effectiveness, efficiency, and ecological obligation.

Applications of Light Weight Aluminum Casting Throughout Industries

While various materials are used in manufacturing, light weight aluminum spreading has become an essential method throughout multiple markets as a result of its adaptability and functionality. This procedure is commonly made use of in the automobile sector for creating lightweight engine blocks, transmission situations, and numerous components that improve gas efficiency. In the aerospace market, light weight aluminum spreading is vital for developing elaborate components that require high strength-to-weight proportions, adding to improved aircraft efficiency.

The electronics market relies on aluminum spreadings for warm sinks and housings, where thermal administration is important for device longevity. The construction sector additionally takes advantage of light weight aluminum casting in the form of building elements and structural elements that combine visual charm with sturdiness. In addition, the durable goods sector utilizes light weight aluminum castings for cookware and showing off tools, leveraging the material's outstanding deterioration resistance and visual finish. Overall, light weight aluminum casting works as a foundation in modern production, supporting varied applications across various areas.

The Role of Light Weight Aluminum Casting in Sustainability

Sustainability has actually become a centerpiece in producing practices, and light weight aluminum casting plays an essential duty in promoting eco pleasant solutions. The procedure of aluminum casting is naturally sustainable as a result of the material's recyclability. Light weight aluminum can be recycled several times without shedding its residential or commercial properties, greatly lowering energy usage and raw material demands. This reusing process eats only around 5% of the energy needed for main light weight aluminum production, leading to a remarkable reduction in carbon exhausts.

Furthermore, aluminum spreading promotes the production of lightweight elements, which add to energy efficiency in different applications, specifically in the automotive and aerospace markets. Lighter vehicles consume less fuel, additional decreasing ecological influence. Additionally, innovations in casting strategies are maximizing product utilization, decreasing waste in producing processes. As industries seek to align with sustainability goals, aluminum spreading becomes a sensible solution, supporting a round economic situation and cultivating liable manufacturing techniques

Technical Improvements in Aluminum Casting Techniques

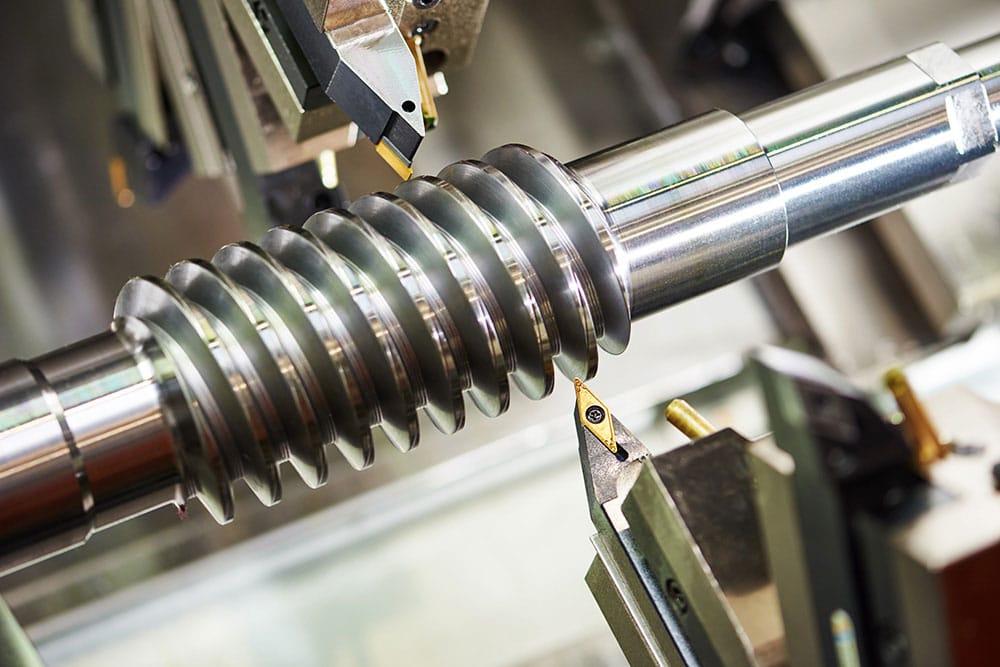

As industries evolve, the fostering of cutting-edge innovations in aluminum casting strategies has actually transformed manufacturing processes. The assimilation of computer-aided style (CAD) and computer-aided manufacturing (CAM) systems enhances accuracy and effectiveness, permitting complex geometries that were formerly challenging to produce. Advanced melting and spreading techniques, such as die spreading and investment spreading, have improved the top quality of light weight aluminum parts, reducing and decreasing flaws waste. The introduction of automated systems and robotics in casting procedures has streamlined operations and boosted productivity. These innovations likewise make it possible for real-time tracking and information analytics, promoting better decision-making and quality assurance. Furthermore, the growth of new alloys and warmth treatment procedures has actually broadened the efficiency capabilities of actors light weight aluminum items. Jointly, these technological advancements not only maximize production performance but likewise add to the sustainability of aluminum casting in modern-day manufacturing.

Future Patterns in Light Weight Aluminum Casting and Its Effect on Technology

Emerging patterns in light weight aluminum spreading are poised to reshape the production landscape, driving technology across different fields. One significant trend is the combination of innovative automation and robotics, which enhances accuracy and performance in manufacturing processes. Additionally, the increase of additive production strategies is permitting more complex styles, minimizing product waste and manufacturing time. As sustainability becomes a priority, the industry's focus on recycling aluminum and using environment-friendly techniques is anticipated to expand, straightening with international ecological objectives.

The growth of wise spreading innovations, including real-time monitoring and data analytics, is established to boost top quality control and functional effectiveness. These improvements will help with the production of lighter, more powerful, and extra my company long lasting light weight aluminum elements, dealing with markets such as automobile and aerospace. Eventually, these trends will certainly not just enhance manufacturing processes yet likewise influence new applications of aluminum spreading, promoting a culture of innovation and flexibility in the marketplace.

Often Asked Concerns

What Is the History of Light Weight Aluminum Spreading in Production?

Exactly How Does Aluminum Spreading Contrast to Other Steels?

Aluminum casting deals advantages such as lightweight residential or commercial properties and corrosion resistance contrasted to other steels. Aluminum Foundry. It improves and assists in complex forms energy performance, making it a favored selection in different manufacturing applications over larger options like steel or iron

What Are the Usual Flaws in Aluminum Casting?

Usual problems in light weight aluminum casting consist of porosity, shrinkage, misruns, and incorporations. These problems can emerge from improper putting techniques, insufficient mold and mildew style, or infected materials, causing diminished architectural honesty and performance of the last product.

Exactly how Is the Top Quality of Aluminum Castings Tested?

The top quality of light weight aluminum castings is checked through methods such as aesthetic examinations, dimensional measurements, non-destructive testing strategies, and mechanical home analyses, guaranteeing that they fulfill defined criteria he said for performance and structural stability.

What Are the Precaution in Aluminum Spreading Processes?

Precaution in light weight aluminum casting processes consist of the use of individual safety equipment, appropriate air flow systems, regular equipment upkeep, training workers on threats, and implementing strict emergency methods to reduce risks connected with heats and molten metal.

The recyclability of light weight aluminum adds to sustainability initiatives, as recycled light weight aluminum requires significantly much less power to procedure contrasted to key light weight aluminum. While numerous materials are employed in manufacturing, aluminum casting has ended up being an essential approach throughout numerous sectors due to its versatility and functionality. Advanced melting and casting methods, such as die casting and investment casting, have improved the high quality of aluminum parts, reducing problems and minimizing waste. Emerging trends in light weight aluminum spreading are positioned to improve the production landscape, driving advancement throughout different fields. Aluminum spreading has advanced considering that the late 19th century, initially creating with the intro of aluminum as a light-weight steel.